Manufacturing

Alorium Technology offers contract electronics manufacturing for low-volume and prototype production builds.

This service now extends beyond our Fusion Product Development clients to include any customer looking for a flexible, quick-turn manufacturing partner for small-quantity PCB assembly production.

Manufacturing Capabilities – At A Glance

Mancorp MC-300 Auto Pick and Place

Vision-inspected pick and place

PCB offset/misalignment correction

Up to 1800 CPH

Mancorp MC-301 Reflow Oven

Programmable reflow profiles

9.84” x 7.87” (250 mm x 200 mm) soldering area capacity

Manual Flows

Visual Inspection

Bring-Up Debug and Rework

General Guidelines

Board / Panel

- Minimum 1.0 inch in at least one direction

- Maximum 200 mm x 300mm

- Minimum 100 mil holes at each of 4 corners

- Board or panel must include fiducials

Parts Handling

- Minimum 0402 component size

- Minimum 0.5 mm pad pitch for QFPs/QFNs/BGAs

- Maximum 28×28 mm part size

- 9 mm max component height

Board Edge Minimums

- Frameless boards: 40 mils

- Framed panels: No restriction

- Require frame between the component and panel edge

Stencil Requirements

- Framed stainless steel stencil

- Maximum 18 in x 18 in

- Minimum 9 in x 9 in

- Minimum 10 mil x 10 mil square openings

Alorium Technology Snō Build

The original catalyst for adding production capabilities was the decision to start manufacturing our own boards starting in 2020.

The video below shows a small build of our Snō FPGA modules in September 2020.

DFM Guidelines

Our Design for Manufacturability (DFM) guidelines provide specifications on what we can support for PCBA manufacturing as well as a summary of our overall capabilities.

Customer BOM Kit Requirements

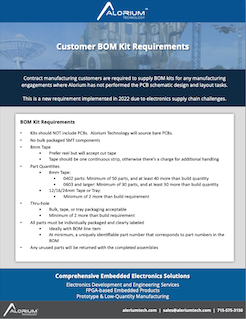

Contract manufacturing customers are required to supply BOM kits for any manufacturing engagements where Alorium has not performed the PCB schematic design and layout tasks. This is a new requirement implemented in 2022 due to electronics supply chain challenges.

Our Customer BOM Kit Requirements outlines what is expected for the BOM kits we receive from customers for contract manufacturing engagements.

Customer BOM Kit Requirements

Contract manufacturing customers are required to supply BOM kits for any manufacturing engagements where Alorium has not performed the PCB schematic design and layout tasks. This is a new requirement implemented in 2022 due to electronics supply chain challenges.

Our Customer BOM Kit Requirements outlines what is expected for the BOM kits we receive from customers for contract manufacturing engagements.

Interested in Manufacturing?